An AGV system that needs no programming in many applications

A key aspect of the iCart design philosophy is that we provide "out of the box" solutions. The iCart is a finished unit, not a kit of parts. You don't program the iCart either, and if you want to implement a KANBAN "on wheels" it can also be done without programming. An application involving 5 AGV's, 10 operator stations, 2 load/unload stations could typically be installed over a single weekend.

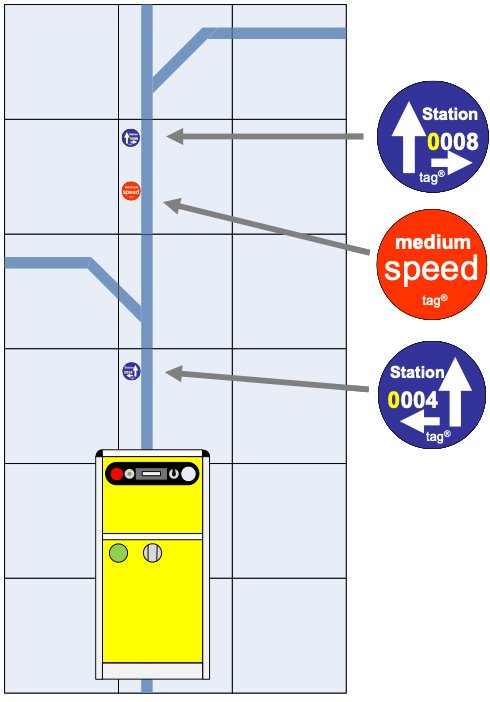

RFID tags, mounted on or in the floor, give directions and commands. The blue tag tells the iCart to turn right at the next junction if it should go to station 4. The red tag tells the iCart to stop at station 5 if this is the destination. It's a manual stop tag so it will wait here for the operator to press the start button to dispatch the iCart to its return destination.

floor tags

The route information is contained along the route itself, just like road signs on motorways. Floor mounted RFID tags contain route information about stations, junctions, corners etc. These are read by the iCart as it travels around. The diagram shows an example of the tags required to set up the route information for identifying routes to stations 4 and 8.

trolley tags

When a specific trolley needs to be routed to specific stations then trolley tags are used. The AGV uses a second reader to read information from trolley mounted tags. These tags contain source and destination information that enable the iCart to automatically travel to the required stations.